3D Printing for Cleaning Road Trucks - The Ultimate Guide

Introduction

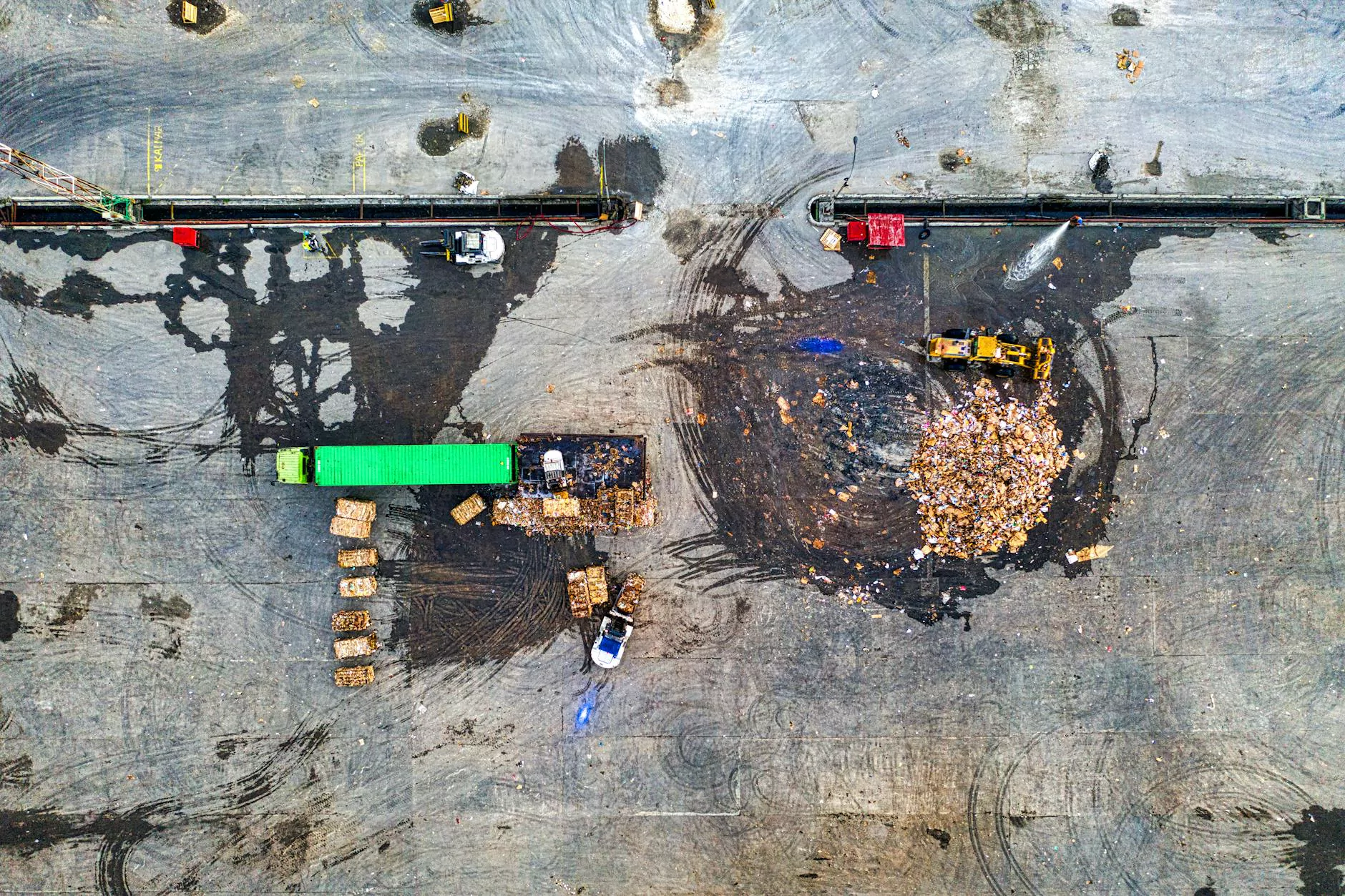

In recent years, the cleaning road truck industry has experienced significant advancements with the emergence of 3D printing technology. With its ability to create complex shapes and intricate designs, 3D printing has revolutionized the manufacturing process, offering numerous benefits and opportunities for road truck cleaning companies. In this comprehensive guide, we will explore the applications, advantages, and future prospects of 3D printing in the cleaning road truck industry.

Benefits of 3D Printing

3D printing brings a host of advantages to the table for the cleaning road truck industry. One of the key benefits is the ability to create highly customized parts and components. Traditional manufacturing processes often rely on mass production techniques, resulting in limited flexibility in design. However, 3D printing enables road truck cleaning companies to manufacture parts tailored to their exact requirements, optimizing functionality and maximizing efficiency.

Another significant advantage of 3D printing is cost-effectiveness. Traditional manufacturing methods involve expensive tooling and setup costs for each new design iteration. With 3D printing, road truck cleaning companies can produce prototypes and test parts quickly and economically. This reduces overall production costs and time, allowing for faster innovation and improved time-to-market for new cleaning road truck technologies.

Applications of 3D Printing in Cleaning Road Trucks

The application of 3D printing in the cleaning road truck industry is vast and diverse. Here are some areas where this technology has shown remarkable potential:

1. Customized Spare Parts

By utilizing 3D printing, cleaning road truck companies can manufacture customized spare parts on-demand. These parts can be easily designed, prototyped, and produced without the need for lengthy lead times or expensive tooling. This ability to create and replace specific components efficiently minimizes downtime and maintenance costs, ensuring optimal performance of the road trucks.

2. Improved Aerodynamics

With 3D printing, road truck cleaning companies can develop aerodynamic designs that enhance the overall performance of their vehicles. By using lightweight and strong materials, they can reduce fuel consumption and increase the efficiency of road trucks. The complex geometries achievable through 3D printing allow for the creation of shapes that optimize airflow, reducing drag and improving the overall aerodynamics of the vehicles.

3. Enhanced Cleaning Mechanisms

3D printing offers road truck cleaning companies the ability to create highly efficient cleaning mechanisms. By designing and producing intricate cleaning nozzles, brushes, and other specialized components, they can enhance the cleaning power of their road trucks. The precision and complexity enabled by 3D printing allow for more effective removal of debris and dirt from surfaces, resulting in improved cleaning performance.

4. Lightweight Structural Elements

Weight reduction is a primary goal in the road truck cleaning industry, as lighter vehicles consume less fuel and are easier to maneuver. With 3D printing, companies can fabricate lightweight yet robust structural elements, such as chassis components and body parts. This not only improves fuel efficiency but also extends the lifespan of the road trucks, reducing maintenance and replacement costs.

The Future of 3D Printing in Cleaning Road Trucks

As 3D printing technology continues to evolve, its potential in the cleaning road truck industry is boundless. Here are some exciting future prospects:

1. On-site Manufacturing

Imagine road truck cleaning companies being able to manufacture spare parts or even entire vehicles directly at their service locations. Advancements in portable and compact 3D printers could make on-site manufacturing a reality, significantly reducing logistics costs and downtime associated with sourcing or waiting for replacement parts.

2. Advanced Material Options

With ongoing research and development, the range of materials compatible with 3D printing is expanding rapidly. Future advancements could introduce new materials tailored specifically for the cleaning road truck industry, offering improved performance and durability. These materials could be designed to withstand harsh environments, chemical exposure, and extreme temperatures, further enhancing the capabilities of road trucks.

3. Integration of Smart Technologies

The combination of 3D printing and smart technologies has the potential to revolutionize the cleaning road truck industry. IoT (Internet of Things) integration, sensors, and advanced data collection capabilities could allow for real-time monitoring, predictive maintenance, and performance optimization. With 3D printing as an integral part of this ecosystem, road truck cleaning companies can achieve new levels of efficiency and cost-effectiveness.

Conclusion

The impact of 3D printing on the cleaning road truck industry cannot be overstated. The ability to create customized parts, improve aerodynamics, enhance cleaning mechanisms, and produce lightweight structural elements has transformed the way road truck cleaning companies operate. As the technology continues to advance, with future possibilities including on-site manufacturing, advanced materials, and smart technology integration, the industry can expect even more significant advancements in the years to come.

With its undeniable benefits, 3D printing is changing the game for the cleaning road truck industry, paving the way for increased efficiency, reduced costs, and improved performance. As road truck cleaning companies embrace this cutting-edge technology, they position themselves at the forefront of innovation and gain a competitive edge in an ever-evolving market.